5 Things to Know Before Buying pharmaceutical intermediates

Key considerations when sourcing pharmaceutical materials

How Pharmaceutical Intermediates Can Add Value To ...

Pharmaceutical Intermediates Can Not Only Help Chemical Manufacturers Enhance the Profitability But Also Achieve Sustainable Growth.

You are some what worried about the future of your chemical manufacturing business. Day by day it's becoming difficult to operate the facility. Everyday new issues are getting added to the list.

And to rub salt into the wound profit margin is thinning down dangerously. You wonder if it is worth taking so much of headache. In spite of your best efforts you are neither able to make decent profit nor able to achieve any business growth. And you doubt whether the situation will remain steady or deteriorate further.

It's time to think differently. But one thing you are sure about. You need to do something about it. And you have to bring in some massive change in your business before it's too late and the situation gets out of hand. You have to find an way out.

You can remember when you were in a seminar last year you have heard about Pharmaceutical Intermediates. You were a bit reluctant then. Though the expert you had met in that seminar was stressing on the fact that it's the best option for a chemical manufacturer to enhance the profitability and achieve sustainable growth.

But today the situation is different. You thought why not give it an honest try. It's 2:00 PM. Will it be right to call the expert now, you thought. You can't wait any further. The urge was so intense that you called the expert then and there. After talking to him you felt a little better. He has agreed to be in your plant tomorrow morning.

You need to do a lot of preparation - inform your team members and keep things ready - so that you can utilize the time of the expert to the maximum extent. You are now sure that some elegant solution will come out tomorrow.

It's 11:00 AM. The expert has already reached your plant. You are waiting for him in the conference room along with your whole team. While you are planning what to discuss with him, he enters. Once the introduction session is over detailed discussion on the issue starts.

Let's highlight the outcome of the meeting.

As an accomplished Industrial Leader, you know how challenging it has become now a days to operate a chemical manufacturing business profitably.

Chemicals Manufacturing is Getting Difficult

- Complying with Environmental Issues: Environmental Issues have risen alarmingly. The Statutory Requirements have become very stringent. The Cost of Waste Treatment is rising day by day.

- Highest Quality Products at Lowest Cost: The global market competition has resulted in sky rocketed customer expectations. Now customers want both Quality and Price - Highest Quality Products at Lowest Price!

- Thinning Down of Profit Margin: The cost of resources are going up - right from the raw materials, to the manpower. And the selling prices of finished products are falling like anything. The Profit Margin is thinning down dangerously.

- Technologies getting Obsolete: The Process Technologies are getting obsolete in an accelerated pace and Products are losing their Market Share very fast.

- High Project Failure Rates: The Project Failure rates are Very High, coupled with Cost Overruns, Project Delays, and other Teething Troubles.

In this scenario, it's essential to grab each and every opportunity to enhance the Profitability and achieve Sustainable Growth.

Profitable Option

Today manufacturing Pharmaceutical Intermediates has emerged as a Profitable Option especially for the leading Chemicals Manufacturers.

hait Product Page

Pharmaceutical Intermediates

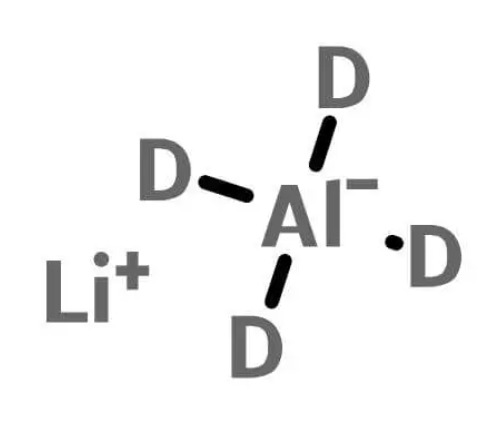

Active Pharmaceutical Ingredients are the major components of Modern Medicines to make them effective enough to cure us from a wide number of deadly diseases. They are fine chemicals having complex molecular structures with multiple functional groups designed to be effective against a wide number of diseases.

Complex chemistry involving multiple difficult unit operations and unit processes are employed to synthesize these molecules. Therefore it becomes extremely difficult to make these molecules in large scale at reasonable cost.

Here comes the importance of Pharmaceutical Intermediates.

The active pharmaceutical ingredients manufacturers are making their job simple and easy by using Pharmaceutical Intermediates. The Intermediates are raw materials and the products of multiple steps of synthesis process. The basic raw materials and the products of initial synthesis steps are grouped separately from the Intermediates which are made in the later stages of the synthesis process. We categorize them as:

- Basic Pharmaceutical Intermediates and

- Advanced Pharmaceutical Intermediates.

Pharmaceutical Intermediates are Important

Both Basic and Advanced Pharmaceutical Intermediates make the synthesis of Active Pharmaceutical Ingredients very easy. Start with advanced Intermediates and do one or two synthesis steps and the product is ready.

Multiple Intermediates are required for making most of the Active Molecules. Active Pharmaceutical Ingredient Manufacturers select the Intermediates - both Advanced and Basic - based on how many synthesis steps they are interested in.

Why It's The Best Option

Now, making Pharmaceutical Intermediates makes business sense

Let's find out why:

- You have already developed expertise in difficult Unit Processes as well as Unit Operations.

- The Safety and Environment systems are in place and optimized enough to take on any challenge. In fact wastes of some processes are valuable resources for other processes resulting in easier Environmental Management.

- You can take the advantages of Integrated Manufacturing by Products Integration as well as Energy Integration. It will result in significant reduction in the Manufacturing Cost.

Business Advantages

There are many plus points. Let's list them out:

- The Sales Turnover to the Investment Ratio is much higher.

- The Profit Margin is quite attractive.

- The Pharmaceutical Intermediates Manufacturers can always go for making Active pharmaceutical ingredients in future. In today's competitive market scenario the availability and the cost of quality Intermediates play a very important role in the success of Active Pharmaceutical Ingredient Manufacturing.

How To Select the Right Pharmaceutical Intermediates

Selecting the right molecules is the starting point and essential for the success of manufacturing Pharmaceutical Intermediates. Utilization of the resources available to you is very important.

Utilization of the Available Resources

Let’s see how you can maximize the utilization of available resources:

- In your Chemical Manufacturing Processes you are handling many molecules - Raw Materials, Inprocess Chemicals, Final Products. Look for maximum Utilization of those molecules.

- You are using many Solvents, Catalysts, Reagents and other Chemicals in your existing Manufacturing Processes. Think of how can you take the advantages of using some of them.

- You have already developed expertise in many Unit Processes and Unit Operations. Select the Pharmaceutical Intermediates where you can utilize your expertise.

- The Manufacturing Facility consists of many Supporting Services - Utility Generation and Supply, Plant and Machinery, and so on. Taking maximum advantages of the resources available to you is the key to select the right Pharmaceutical Intermediates.

- Think of using the expertise developed by your critical functional areas – Purchase, Sales & Marketing, Finance, Commercial and others – in order to select the right molecules.

Let’s discuss how you can select the right molecules based on Product Categories and Unit Processes Involved.

Based on Product Categories

The information on the type of Medicines help a lot to estimate the market of the Intermediates. There are thousands of active pharmaceutical ingredients for a wide number of diseases. The demand of these active molecules are based on their medicinal uses. And usage of these molecules in the modern medicines is increasing day by day due to various factors.

A detailed knowledge on the synthesis processes will help you choose the right pharmaceutical intermediates.

Based On The Unit Processes and Unit Operations

You need to employ various Unit Operations and Unit Processes to make the active pharmaceutical ingredients. You know which unit processes and unit operations you can handle effectively. In addition to it the plant and machinery requirements for various unit processes are different.

Once you have sufficient knowledge about the route of synthesis and the critical processes involved you shall be able to select the right pharmaceutical intermediates to manufacture.

Of course you need to do detailed study to ensure technical feasibility and economic viability for each and every product before concluding. And the whole manufacturing and marketing planning is there to be done. But it's what you do day in day out in your organization.

Now you are crystal clear what to do and how to do. And the expert has already accepted your offer for providing support in order to make the project successful. You have already chalked out a plan. And you are extremely confident of making it happen. You are excited about adding tremendous value in all most all aspects of your business.

Let's Conclude

Manufacturing Pharmaceutical Intermediates is an option you need to explore.

Think of how you can utilize the resources available to you to the maximum extent while selecting the products, deciding on the synthesis route, developing the process, scaling up to the commercial level production, designing the plant, and planning for manufacturing.

Once you start getting into the details with an intention to innovate, you will be surprised to find multiple opportunities to add tremendous value in various functions of your business. As you dig deeper the innovation process will become auto-catalytic. And that's what you need to take your business to the next level.

However for Quick and Effective Results You can consider:

- An Integrated Manufacturing Evaluation by an Industry Expert

- Efficient Operation of the Manufacturing Facility by Knowledgeable and Trained Manpower

What's your experience with the Manufacturing of Pharmaceutical Intermediates?

Which areas need maximum focus?

How can you use the advances in technology to make Pharmaceutical Intermediates Manufacturing Profitable and sustainable?

Chemical HEC Hydroxyethyl Methyl Cellulose Price for ...

5 Things to Know Before Buying 4-amino-3,5-dichloroacetophenone manufacturers

Magnesium Oxide

Revolutionary Cellulose Straws: Environmental Game Changer?

How Cellulose Products Improve Durability of Wall Putty

Revolutionizing the Paint Industry with HPMC: How?

What's your opinion about Manufacturing Basic Pharmaceutical Intermediates compared to Advanced Pharmaceutical Intermediates?

Additional reading:Hydroxypropyl Methylcellulose

Key considerations when sourcing pharmaceutical materials

Finding the right supplier for your pharmaceutical intermediatespharmaceutical intermediates and ingredients will make or break your business.

As the pharmaceutical industry becomes more competitive and processes more rigorous, manufacturers are hard pressed to manage a complex network of raw material suppliers including for pharmaceutical ingredients. For example, China’s pharmaceutical industry alone needs more than 2,000 types of raw materials and intermediates to meet its market demand each year.

When we talk about pharmaceutical ingredients, it usually involves the following components: pharmaceutical intermediates and active pharmaceutical ingredients (APIs). For the layman, pharmaceutical intermediates are chemical compounds that form the building blocks used to produce APIs, while APIs are the substances used in the manufacture of drug products.

Here are some key considerations you need to think about when sourcing for materials for your business:

1. Complex regulations. The pharmaceutical supply chain is a complex process. There are stringent manufacturing processes to abide by and intricate regulatory requirements to be familiar with in each respective market you are intending to enter.

2. Dynamic market. The constantly changing market and pricing trends and the rising number of specialized drugs available in the market today have also resulted in the increase in the complexity of these compounds and raw materials used to develop new drugs.

3. Consumer safety. As these ingredients are used in a highly regulated market, any alteration to the quality of raw materials or any single change can affect the final product’s quality and consumer safety. Any mishap at this stage could prove costly for your business.

4. Disruption to supply chain. Despite the industry being a highly regulated one, untoward accidents do occur. Whether it is disruption to the supply of intermediates and APIs following natural disasters or contamination of raw materials, often, the entire industry, from manufacturers right up to consumers, is affected.

5. Environment conscious and transparency. With consumers becoming more conscious of the choices available in the market, manufacturers are seeking out suppliers with credible environment-conscious processes, good manufacturing practices and eco-friendly products. For manufacturers looking to source raw materials from suppliers in emerging markets, a major challenge is to ensure supply chain transparency.

6. Choosing a certified source. Manufacturers must seek out suppliers that have in place fully compliant audit and process controls throughout their supply chain. These suppliers must, for example, can readily share data about their manufacturing procedures, technical capabilities and quality control measures taken.

A good place to source for pharmaceutical intermediates and APIs will be the upcoming Chemspec Europe exhibition. To be held in Munich, Germany, from May 31-June 1, the event features leading manufacturers, suppliers and distributors of fine and specialty chemicals from all over the world.

Together with the more than 320 exhibitors from 24 countries, DKSH will be showcasing its diverse portfolio including APIs, intermediates, excipients, coupling agents and activating agents. Come and meet us at Chemspec Europe, or drop me a thought here on what your current challenges in finding the right sources for pharmaceutical materials, intermediates or APIs are.

Biography:

Tanja Schaffer is a doctor in chemistry, based in Switzerland. She is currently responsible for DKSH’s Business Line Pharmaceutical Industry globally (excluding Japan).

How Pharmaceutical Intermediates Can Add Value To ...

Pharmaceutical Intermediates Can Not Only Help Chemical Manufacturers Enhance the Profitability But Also Achieve Sustainable Growth.

You are some what worried about the future of your chemical manufacturing business. Day by day it's becoming difficult to operate the facility. Everyday new issues are getting added to the list.

And to rub salt into the wound profit margin is thinning down dangerously. You wonder if it is worth taking so much of headache. In spite of your best efforts you are neither able to make decent profit nor able to achieve any business growth. And you doubt whether the situation will remain steady or deteriorate further.

It's time to think differently. But one thing you are sure about. You need to do something about it. And you have to bring in some massive change in your business before it's too late and the situation gets out of hand. You have to find an way out.

You can remember when you were in a seminar last year you have heard about Pharmaceutical Intermediates. You were a bit reluctant then. Though the expert you had met in that seminar was stressing on the fact that it's the best option for a chemical manufacturer to enhance the profitability and achieve sustainable growth.

But today the situation is different. You thought why not give it an honest try. It's 2:00 PM. Will it be right to call the expert now, you thought. You can't wait any further. The urge was so intense that you called the expert then and there. After talking to him you felt a little better. He has agreed to be in your plant tomorrow morning.

You need to do a lot of preparation - inform your team members and keep things ready - so that you can utilize the time of the expert to the maximum extent. You are now sure that some elegant solution will come out tomorrow.

It's 11:00 AM. The expert has already reached your plant. You are waiting for him in the conference room along with your whole team. While you are planning what to discuss with him, he enters. Once the introduction session is over detailed discussion on the issue starts.

Let's highlight the outcome of the meeting.

As an accomplished Industrial Leader, you know how challenging it has become now a days to operate a chemical manufacturing business profitably.

Chemicals Manufacturing is Getting Difficult

- Complying with Environmental Issues: Environmental Issues have risen alarmingly. The Statutory Requirements have become very stringent. The Cost of Waste Treatment is rising day by day.

- Highest Quality Products at Lowest Cost: The global market competition has resulted in sky rocketed customer expectations. Now customers want both Quality and Price - Highest Quality Products at Lowest Price!

- Thinning Down of Profit Margin: The cost of resources are going up - right from the raw materials, to the manpower. And the selling prices of finished products are falling like anything. The Profit Margin is thinning down dangerously.

- Technologies getting Obsolete: The Process Technologies are getting obsolete in an accelerated pace and Products are losing their Market Share very fast.

- High Project Failure Rates: The Project Failure rates are Very High, coupled with Cost Overruns, Project Delays, and other Teething Troubles.

In this scenario, it's essential to grab each and every opportunity to enhance the Profitability and achieve Sustainable Growth.

Profitable Option

Today manufacturing Pharmaceutical Intermediates has emerged as a Profitable Option especially for the leading Chemicals Manufacturers.

Pharmaceutical Intermediates

Active Pharmaceutical Ingredients are the major components of Modern Medicines to make them effective enough to cure us from a wide number of deadly diseases. They are fine chemicals having complex molecular structures with multiple functional groups designed to be effective against a wide number of diseases.

Complex chemistry involving multiple difficult unit operations and unit processes are employed to synthesize these molecules. Therefore it becomes extremely difficult to make these molecules in large scale at reasonable cost.

Here comes the importance of Pharmaceutical Intermediates.

The active pharmaceutical ingredients manufacturers are making their job simple and easy by using Pharmaceutical Intermediates. The Intermediates are raw materials and the products of multiple steps of synthesis process. The basic raw materials and the products of initial synthesis steps are grouped separately from the Intermediates which are made in the later stages of the synthesis process. We categorize them as:

- Basic Pharmaceutical Intermediates and

- Advanced Pharmaceutical Intermediates.

Pharmaceutical Intermediates are Important

Both Basic and Advanced Pharmaceutical Intermediates make the synthesis of Active Pharmaceutical Ingredients very easy. Start with advanced Intermediates and do one or two synthesis steps and the product is ready.

Multiple Intermediates are required for making most of the Active Molecules. Active Pharmaceutical Ingredient Manufacturers select the Intermediates - both Advanced and Basic - based on how many synthesis steps they are interested in.

Why It's The Best Option

Now, making Pharmaceutical Intermediates makes business sense

Let's find out why:

- You have already developed expertise in difficult Unit Processes as well as Unit Operations.

- The Safety and Environment systems are in place and optimized enough to take on any challenge. In fact wastes of some processes are valuable resources for other processes resulting in easier Environmental Management.

- You can take the advantages of Integrated Manufacturing by Products Integration as well as Energy Integration. It will result in significant reduction in the Manufacturing Cost.

Business Advantages

There are many plus points. Let's list them out:

- The Sales Turnover to the Investment Ratio is much higher.

- The Profit Margin is quite attractive.

- The Pharmaceutical Intermediates Manufacturers can always go for making Active pharmaceutical ingredients in future. In today's competitive market scenario the availability and the cost of quality Intermediates play a very important role in the success of Active Pharmaceutical Ingredient Manufacturing.

How To Select the Right Pharmaceutical Intermediates

Selecting the right molecules is the starting point and essential for the success of manufacturing Pharmaceutical Intermediates. Utilization of the resources available to you is very important.

Utilization of the Available Resources

Let’s see how you can maximize the utilization of available resources:

- In your Chemical Manufacturing Processes you are handling many molecules - Raw Materials, Inprocess Chemicals, Final Products. Look for maximum Utilization of those molecules.

- You are using many Solvents, Catalysts, Reagents and other Chemicals in your existing Manufacturing Processes. Think of how can you take the advantages of using some of them.

- You have already developed expertise in many Unit Processes and Unit Operations. Select the Pharmaceutical Intermediates where you can utilize your expertise.

- The Manufacturing Facility consists of many Supporting Services - Utility Generation and Supply, Plant and Machinery, and so on. Taking maximum advantages of the resources available to you is the key to select the right Pharmaceutical Intermediates.

- Think of using the expertise developed by your critical functional areas – Purchase, Sales & Marketing, Finance, Commercial and others – in order to select the right molecules.

Let’s discuss how you can select the right molecules based on Product Categories and Unit Processes Involved.

Based on Product Categories

The information on the type of Medicines help a lot to estimate the market of the Intermediates. There are thousands of active pharmaceutical ingredients for a wide number of diseases. The demand of these active molecules are based on their medicinal uses. And usage of these molecules in the modern medicines is increasing day by day due to various factors.

A detailed knowledge on the synthesis processes will help you choose the right pharmaceutical intermediates.

Based On The Unit Processes and Unit Operations

You need to employ various Unit Operations and Unit Processes to make the active pharmaceutical ingredients. You know which unit processes and unit operations you can handle effectively. In addition to it the plant and machinery requirements for various unit processes are different.

Once you have sufficient knowledge about the route of synthesis and the critical processes involved you shall be able to select the right pharmaceutical intermediates to manufacture.

Of course you need to do detailed study to ensure technical feasibility and economic viability for each and every product before concluding. And the whole manufacturing and marketing planning is there to be done. But it's what you do day in day out in your organization.

Now you are crystal clear what to do and how to do. And the expert has already accepted your offer for providing support in order to make the project successful. You have already chalked out a plan. And you are extremely confident of making it happen. You are excited about adding tremendous value in all most all aspects of your business.

Let's Conclude

Manufacturing Pharmaceutical Intermediates is an option you need to explore.

Think of how you can utilize the resources available to you to the maximum extent while selecting the products, deciding on the synthesis route, developing the process, scaling up to the commercial level production, designing the plant, and planning for manufacturing.

Once you start getting into the details with an intention to innovate, you will be surprised to find multiple opportunities to add tremendous value in various functions of your business. As you dig deeper the innovation process will become auto-catalytic. And that's what you need to take your business to the next level.

However for Quick and Effective Results You can consider:

- An Integrated Manufacturing Evaluation by an Industry Expert

- Efficient Operation of the Manufacturing Facility by Knowledgeable and Trained Manpower

What's your experience with the Manufacturing of Pharmaceutical Intermediates?

Which areas need maximum focus?

How can you use the advances in technology to make Pharmaceutical Intermediates Manufacturing Profitable and sustainable?

What's your opinion about Manufacturing Basic Pharmaceutical Intermediates compared to Advanced Pharmaceutical Intermediates?

Additional reading:Key Questions to Ask When Ordering TURF LATEX Artificial Turf SBR Latex

Function of Redispersible Polymer Powder(RDP) in dry ...

How to Choose Re-Dispersible Polymer Powder For Tile Adhesive? Mastering the Selection Process

HPMC - Shanghai Honest Chem. Co., Ltd. - page 1.

4 Key Tips to Select an Intermittent Hypoxia-Hyperoxia Treatment

Is Polyurethane Backed Artificial Grass Worth It?

How innovative are Construction Chemical Solutions now?

- 261

- 0

- 0

- Previous: Hydroxypropyl Methylcellulose

- Next: Everything You Need to Know About Methyl Hydroxyethyl Cellulose for Etics/Eifs